Cold & Frozen Storage

Introduction

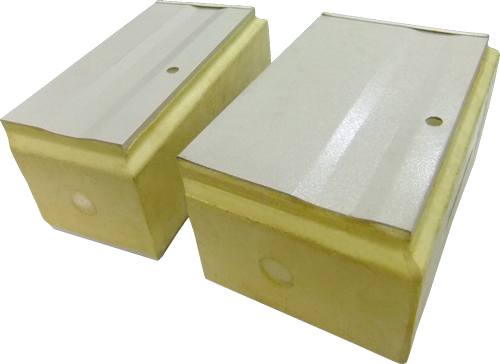

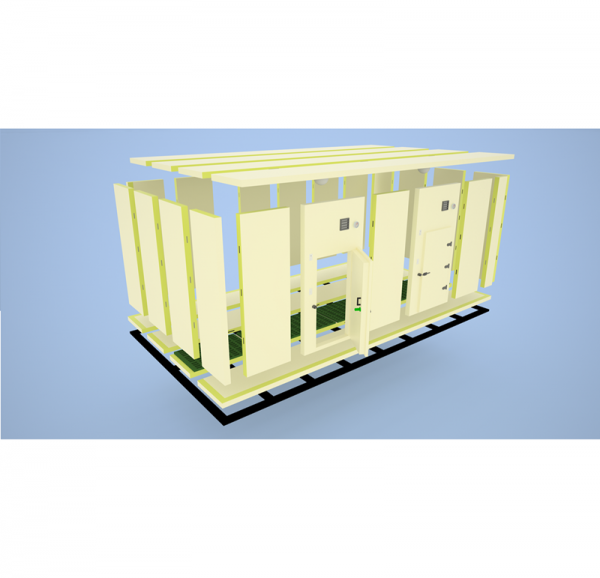

The panels comprise of two steel skins that are injected with a high pressure polyurethane foam, thus creating an insulated sandwich panel. You can start small and add on additional modules in future.

Khopang's PU modular panel in which the insulated core is injected foam of PU.

Key Feature

![]() Fire resistanceFire resistance regulation CNS14705, Class 2.

Fire resistanceFire resistance regulation CNS14705, Class 2.

![]() Lightweight

Lightweight

![]() Thermal Insulation

Thermal Insulation

![]() Acoustic Insulation

Acoustic Insulation

![]() High Tensile Strength

High Tensile Strength

![]() Resistant to wear

Resistant to wear

![]() Water Resistance

Water Resistance

![]() Easy for tool cutting

Easy for tool cutting

![]() Standard Manufacturing Sizes

Standard Manufacturing Sizes

Thickness

| Thickness | Function | Temperature | |

|---|---|---|---|

| 60mm | Freezer Storage | 0 ℃ ~ +20 ℃ | |

| 110 mm | Cold Storage | -25 ℃ ~ 0 ℃ | |

| 150mm | Frozen Storage | < -25 ℃ | |

Specification

| Item | Specification | |

|---|---|---|

| Thickness | 60 / 110 / 150 mm | |

| Width | 900mm | |

| Max. Panel Length | 11760mm | |

| Constrction | Skin | 0.5mmt Galvanized Steel 0.5mmt Stainless Steel |

| Core | Rigid Polyurethane Foam | |

| Joint | Double Tongue and Groove joint | |

| Fire Resistance Regulation | CNS 14705 Class 2 |

|

Key Feature

Panel Face Skins

-

White Food Safe Laminate

Galvanized mild steel with slightly textured PVC facing and removable protective film, suitable for food process purposes.

-

Stainless Steel

Mild steel with Chromium and Nickel coat, which achieves antioxidant, high mechanical strength, and durable.